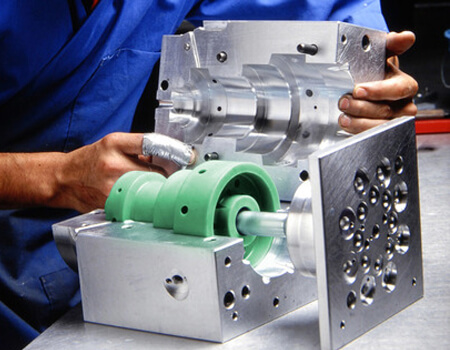

We have facility and experience for Die Making on VMC M/C for any Critical Geometry Components.

We have facility and experience for Die Making on VMC M/C for any Critical Geometry Components.

Before sampling, we do 100% Die Dimensional Inspection, as per drawings.

Before sampling, we do 100% Die Dimensional Inspection, as per drawings.

Final Casting quality depends solely on the wax pattern Quality

Final Casting quality depends solely on the wax pattern Quality

Assembly Design is done to produce best yield with best quality.

Assembly Design is done to produce best yield with best quality.

We use, Zircon flour & sand, fused Silica and Colloidal Silica (water based) binder for different applications.

We use, Zircon flour & sand, fused Silica and Colloidal Silica (water based) binder for different applications.

We have Equipments like Slurry Drums, Rain fall Sander, Fluidized Bed, Jar –Drum etc.

We have Equipments like Slurry Drums, Rain fall Sander, Fluidized Bed, Jar –Drum etc.

Our Melting Shop is equipped with Inductotherm Make Induction Furnace, with 400 and 150 Kg. Crucibles and Temperature Controlled Shell Baking furnace.

Our Melting Shop is equipped with Inductotherm Make Induction Furnace, with 400 and 150 Kg. Crucibles and Temperature Controlled Shell Baking furnace.

We use standard quality scrap to ensure best metallurgical quality of casting materials.

We use standard quality scrap to ensure best metallurgical quality of casting materials.

In-house facility for heat treatment like; Solution Annealing, Normalizing, Tempering, with temperature controlled Gas fired Heat Treatment Furnace.

In-house facility for heat treatment like; Solution Annealing, Normalizing, Tempering, with temperature controlled Gas fired Heat Treatment Furnace.

Best Heat treatment practice is ensured through study of microstructure.

Best Heat treatment practice is ensured through study of microstructure.

Our Fettling Shop is equipped with Machines for Shot Blasting, Abrasive Blasting, Belt Disc- Grinding, Welding, Pneumatic Grinding and supporting machinery.

Our Fettling Shop is equipped with Machines for Shot Blasting, Abrasive Blasting, Belt Disc- Grinding, Welding, Pneumatic Grinding and supporting machinery.

We supply casting without any gate and riser pads.

We supply casting without any gate and riser pads.

Ability to conduct various Tests like; Pressure Testing, Non Destructive Testing (DP and Radiography), IGCT, Impact Testing, etc. through In-house and external agencies.

Ability to conduct various Tests like; Pressure Testing, Non Destructive Testing (DP and Radiography), IGCT, Impact Testing, etc. through In-house and external agencies.

Process capability like; Glass Bead Blasting, Vibro-finishing, Buffing, Electro Polishing and Acid Passivation, as per customer’s requirement.

Process capability like; Glass Bead Blasting, Vibro-finishing, Buffing, Electro Polishing and Acid Passivation, as per customer’s requirement.

We apply 100% visual inspection followed by dimensional inspection.

We apply 100% visual inspection followed by dimensional inspection.